Talk with Us : +86-13306168278

Source:JYC technology Co.,ltd. Release time:2021-07-20 20:53:10 Author:9512

Permanent magnetic chuck is designed based on continuity of magnetic flux and superposition of magnetic fields. The magnetic circuit of the permanent magnetic chuck is designed into multiple magnetic systems. Through the relative movement of the magnetic systems, the addition or Cancellation to achieve the purpose of holding and unloading workpieces at all kinds of machines.

Features

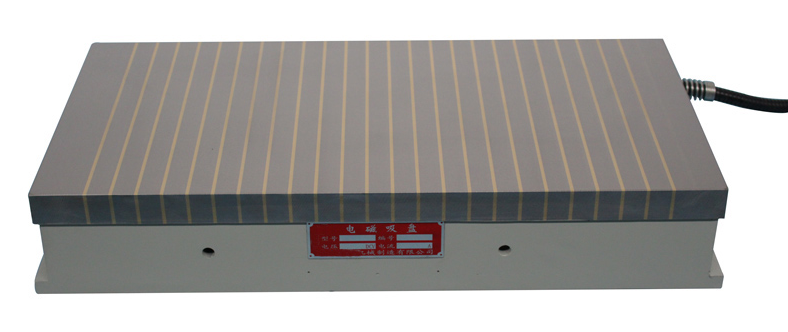

Magnetic force of electromagnetic chuck is generated by energizing its internal coils, magnetism pass through the magnetic panel, make the workpiece contacting the surface of the panel tightly attracted, and the demagnetization is realized by the coil power off, the magnetic force disappears, then you can move away the workpieces.

Features

Electro permanent magnetic chuck is a kind of magnetic clamp that uses electric energy to control and uses permanent magnets to work.

When the chuck uses a dedicated rectifier controller to pass the forward current, the magnetic force of the internal permanent magnet material is superimposed, and the magnetic force is displayed to the outside, and the workpiece is held for processing or transport. When the reverse current is passed, the magnetic force closed inside, and then workpieces can be removed.

Features