Talk with Us : +86-13306168278

Features

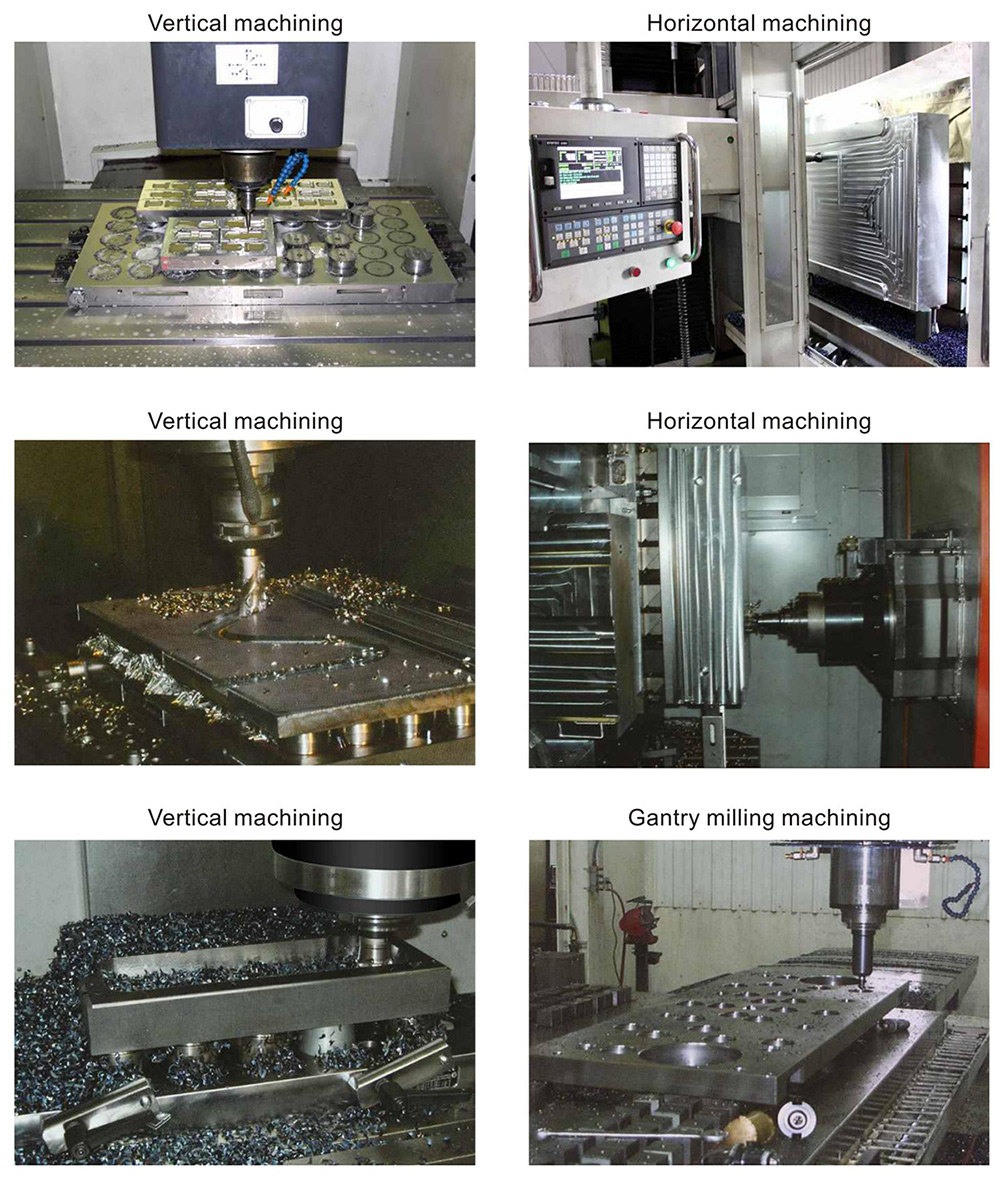

·Suitable for CNC milling machine

·Suction up to 180 N/cm2..

·No power need when it work, easy to operate, small heating deformation,no affection at the processing accuracy

·Pole pitch:50x50mm, 70x70mm, customized

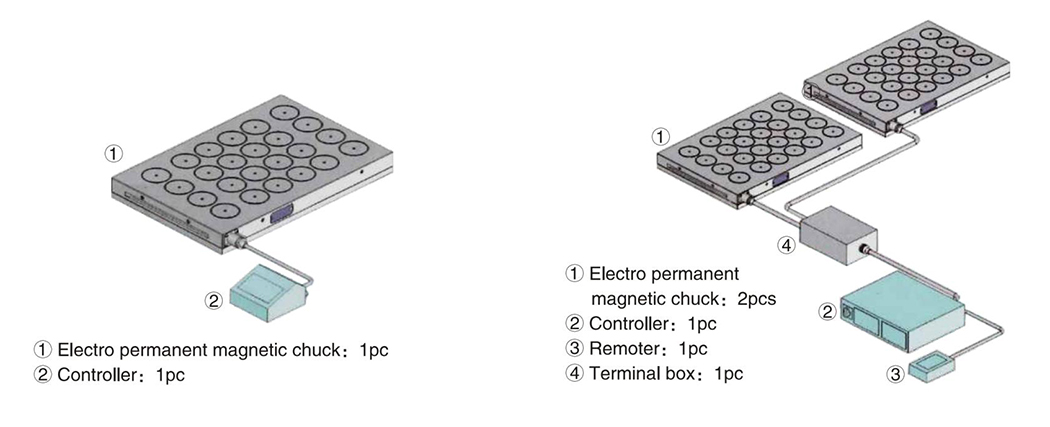

If you don't have the control system to control the working state of this chuck, please ask our sales for more information. Multiple control and remote control are all available.With AC 0-380V, suitable for all kinds of situation.

According to the machine table size, you can choose the number of chucks.

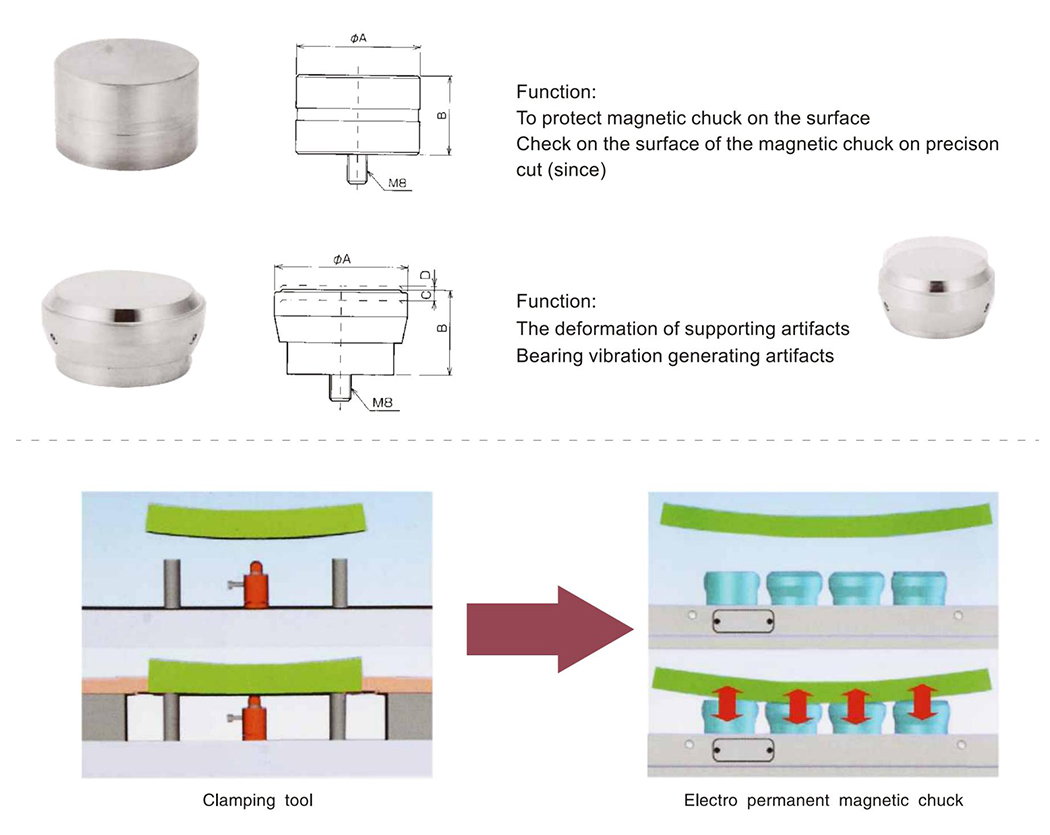

Magnetic blocks for extensions.

Square or round magnetic blocks can extend the magnetic force from the chuck, which can protect magnetic chuck from wearing out and make its service life longer. Besides, it can provide you more different clamping solutions for all kinds of maching.

Different magnet types

There are three types of magnet, permanent magnetic chuck, electromagnetic chuck, electropermanent magnetic chuck, each one has their advantages.

Read more

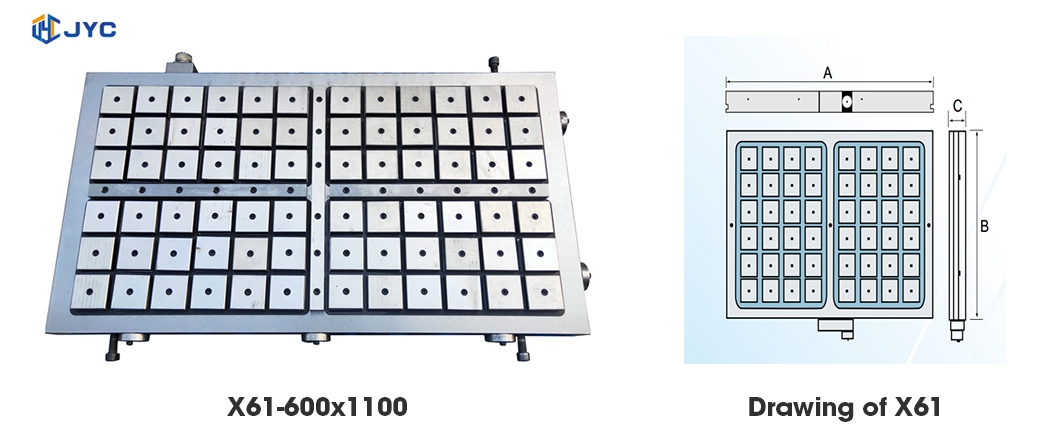

| Model | Dimensions (MM) | Polar Distance (MM) | Polar number | Net Weight (KG) | |||

| Length | Breadth | Height | 70*70 | 50*50 | |||

| X61-250*250 | 250 | 250 | 68 | 70*70/50*50 | 4 | 9 | 31 |

| X61-250*300 | 300 | 250 | 6 | 12 | 40 | ||

| X61-300*300 | 300 | 300 | 9 | 16 | 48 | ||

| X61-300*400 | 400 | 300 | 12 | 20 | 64 | ||

| X61-300*500 | 500 | 300 | 15 | 28 | 80 | ||

| X61-300*600 | 600 | 300 | 18 | 32 | 96 | ||

| X61-300*800 | 800 | 300 | 24 | 48 | 128 | ||

| X61-300*1000 | 1000 | 300 | 30 | 60 | 160 | ||

| X61-400*400 | 400 | 400 | 16 | 25 | 85 | ||

| X61-400*500 | 500 | 400 | 20 | 35 | 105 | ||

| X61-400*600 | 600 | 400 | 24 | 40 | 128 | ||

| X61-400*800 | 800 | 400 | 32 | 60 | 170 | ||

| X61-400*1000 | 1000 | 400 | 40 | 75 | 210 | ||

| X61-500*500 | 500 | 500 | 80 | 25 | 49 | 155 | |

| X61-500*600 | 600 | 500 | 30 | 56 | 188 | ||

| X61-500*800 | 800 | 500 | 40 | 84 | 250 | ||

| X61-500*1000 | 1000 | 500 | 50 | 105 | 310 | ||

| X61-600*600 | 600 | 600 | 36 | 72 | 225 | ||

| X61-600*800 | 800 | 600 | 48 | 96 | 300 | ||

| X61-600*1000 | 1000 | 600 | 60 | 120 | 375 | ||

| X61-600*1200 | 1200 | 600 | 72 | 144 | 450 | ||

| X61-600*1500 | 1500 | 600 | 90 | 176 | 560 | ||

|

Note: Other specifications can be customized ,please call for further information. Suggestion: You can choose two installation methods (through hole/pressing block). |

|||||||